The economic significance of the forest-wood sector

More than 25,000 persons generate income from the forest-wood sector. Part of the income stems from the management of the forests. More than 15,000 families take their income directly from the forest. The largest part of this added value is generated in subsequent processing as well as through cooperation with the supplier industry. Subsequent processing includes turning the timber raw material into semi-finished goods or finished products for local and international markets. More than 2,200 firms in the manufacturing industry are active in this sector. In addition there are the various specialist technicians who work in the service sector: agronomists, foresters, architects and engineers, who are either directly or indirectly involved in the use of this raw material. More than 80 percent of these firms are located in rural areas outside the larger conurbations (Bozen-Bolzano, Meran-Merano, Brixen-Bressanone, Bruneck-Brunico, Leifers-Laives, Sterzing-Vipiteno and Schlanders-Silandro). The entrepreneurs active in the sector thus forge strong bonds between the production sites and the areas where they are located. The firms employ both manual workers and technicians, experts and skilled workers. Part of the workforce is employed only part time in the factories. This enables these workers to tend to their agricultural holdings, which further generates additional income for the families working in hill farming and mountain agriculture. Cautious estimates suggest that the entire forest-wood sector economy generates an annual turnover of roughly 1.2 billion euros. And at the personal level too, South Tyrol is closely linked to the forest and to wood: almost everyone knows at least one person who is active in this industry.

Ian Schneider

Dorelys Smits

Local Round Timber

The high quality of the local timber has always enjoyed great prestige in Italy and is increasingly valued on the international market as well. In comparison to many other countries, timber in South Tyrol grows mainly at altitudes above 1,000 m above sea level. As a consequence, the trees grow relatively slowly and the wood fibres are thus particularly fine grained. Wood from local forests has an excellent staying power and is, in comparison to softwood from other regions, considerably better suited for many more applications. Last but not least, demand for South Tyrol round timber has increased steadily in recent decades, due to its excellent technical properties.

Regional added value

The term “added value” can be defined as the unit value of the final product which exceeds the value of the original product. It is thus a dynamic value which is created during processing. The aim of all economic activity should be to achieve maximal added value per unit (utility). If the processing of a product takes place within a region the number of procedures within the region increases which in turn strengthens the local economy. To measure this value, we need to define the individual processes within the various phases of the production of the relevant product. The estimated annual turnover of the forest-wood sector is over 1.3 billion euros.

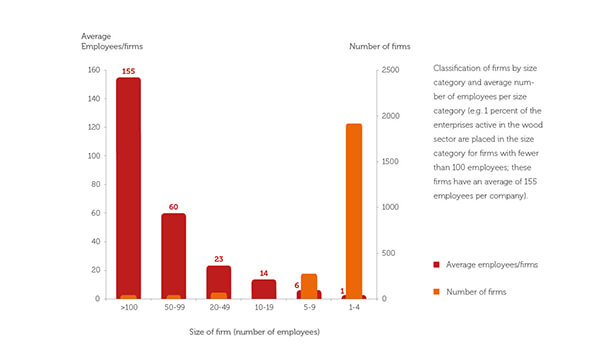

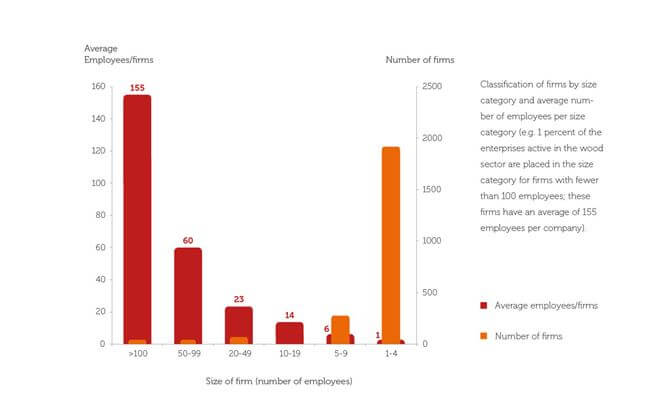

Timber processing businesses

Classification of firms by size category and average number of employees per size category (e.g. 1 percent of the enterprises active in the wood sector are placed in the size category for firms with fewer than 100 employees; these firms have an average of 155 employees per company).

Wood biomass

Development of technology for large-scale facilities has been promoted enthusiastically at regional level by local authorities. Today there are 72 biomass power plants in operation throughout the region. For these power plants more than 500,000 m3 of wood are required, two thirds of which come from South Tyrol. 45 percent of the material required to run the plants (more than 230,000 m3) comes from firms in the wood sector and results from the processing of the raw material. The remaining amount (35 percent of the domestic consumption, around 180,000 m3) is supplied from neighbouring regions. Currently these biomass-fired power plants generate almost 720 million kWh of heat, replacing the equivalent quantity of fossil fuel! You can find a list of all members on the website of the South Tyrol Energy Association.